The Importance Of New Technologies In Supply Chain

SUPPLY CHAIN AND LOGISTICS TRENDS THAT COULD BE BIG IN 2020

October 13, 2020The revolution of technology has changed the entire world, specially all aspects of business operations. Tough competition, gradual transitions as well as the changes in customer expectations, including decreased product lifestyles and product proliferation, create compulsion that affects heavily the business world. In order to keep pace with the rapidly changing or growing global market and to remain on the cutting edge of an intricate business environment, more companies are assimilating latest technologies into their supply chain management systems. At the outset of new generation of eCommerce and mCommerce, business stays at the forefront in building sustainable strategies and adapting to innovative technologies. They are helpful for cooperation & coordination within the supply chain and plays a key role in simplifying and building resilient logistics operations.

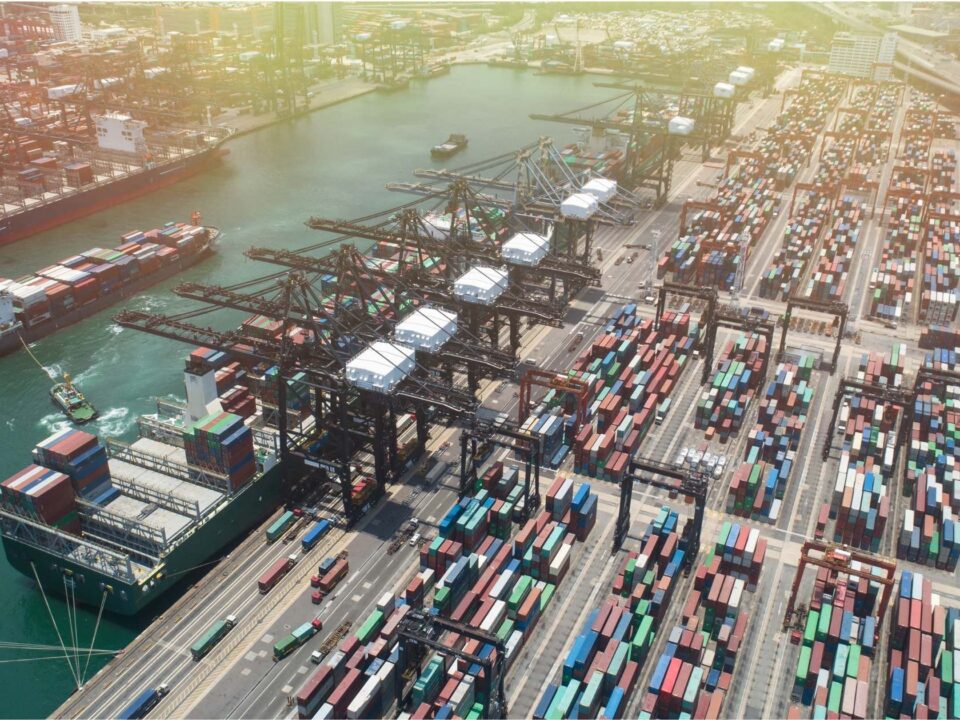

As a key infrastructure, web-based technologies are transforming daily business processes for many in supply chain management and continue to have significant impact on supply chain operations, spanning production, distribution, retailing and remote servicing etc. The requirement of real-time tracking and accurate delivery systems makes supply chain management ready for technological innovation, whereas smartphones, wireless connections, all handheld technology is leading the way throughout the logistics sector. Therefore, the adoption of trendy technologies and its methodical implementation can upgrade the cooperation and agility of supply chains through the rapid transfer, the distribution of precise information and the proper use of information.

Here are a few of the ways in which technology is impacting profoundly supply chain management:

1) Greater visibility and hence overall efficiency

Nowadays shippers want better services and more transparency from their supply chain managers, ideally at affordable costs. Since the start of the wireless generation, many supply chain managers have turned to wireless technologies and cloud computing to computerised systems and improve accuracy.

Not only are these systems quicker and more effective than their manual, fax-based predecessors, the mobile and computerised methodologies also provide better data-capture, which can, in and of themselves, improve operations and can also be stored and examined to target areas for advancement.

One of the popular technologies for automatic identification and data-capture is radio-frequency identification (RFID) as it tags can be affixed to inventory, clothing, or almost any item, the tracing possibilities are substantial and applicable to numerous facets of the supply chain.

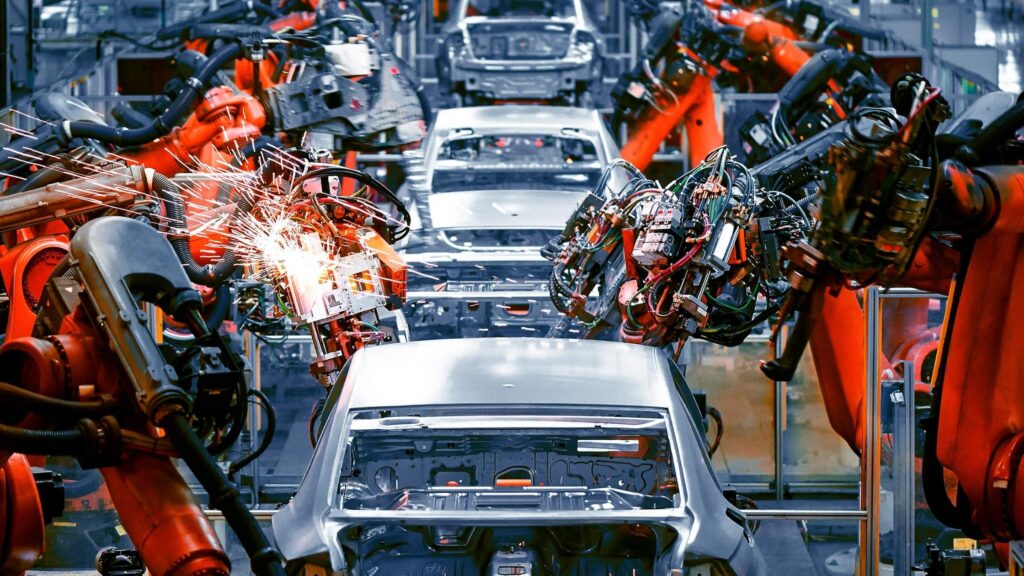

By opting new technology to attain better visibility across all areas of the business and make data driven arrangements based on real time data, technology brings efficiency across the whole manufacturing and delivering process.

2) Rapid transfer of information all across the supply chain.

With the technology implemented, real time information sharing, manufacturers can increase the communication with their key partners because of the rapid transfer of information from manufacturers to distributers. Manufacturers can easily track activities through the whole supply chain, with transparency into supplier end and distributor processes. Such information can benefit the manufacturers in making more informed decisions and better prediction of future demands.This helps regulate the manufacturing process efficiently and leads to lower prices through more relevant and productive decisions in procurement and contract management.

3) Better control over production.

Use of technology in supply chain management gives improved clarity and accountability. In order to bring adeptness and accuracy to the whole production process, it is crucial that a manufacturing company have clear knowledge of the current stage of in-production products, anticipate any potential issues or delays they might face and be able to fix production schedules accordingly. Use of technology can bring the indispensible visibility into the whole process. It lets the manufacturing companies to have better and firm control over product flow and information flow all across the supply chain.

The improved information flow also has more probability of better asset utilization equipping loads to help the shipper return home with freight, decreasing empty miles from the transportation network.

4) More effective inventory management.

Inventory management said to be the process of ordering, storing and using a company’s goods or materials. A successful inventory management enables businesses to meet the demand level of their consumers with an ample amount of supply. Ineffective management can cause overflowed inventory which includes the risk of spoilage, damage or a shift in demand that leads stock to accumulate even further whereas too low of inventory may cause to stoppages in the production cycle and of losing business through stockouts. If inventory isn’t sold before these things happen, then it is usually sold at clearance prices or destroyed.

An advanced supply chain management starts with technology. Excluding traditional and often manual strategies saves time and lowers the risk of error. Managing processes digitally makes any information recorded easier to share across an entire supply chain.To be already halfway to full supply chain optimization, one needs to implement a transportation management system (TMS) in his company.

Connecting with customers about product availability and fixed shipping dates becomes almost impossible when exact and up-to-date information is missing. With the use of technology, manufacturers can innovate adaptable business operations that give flexibility to deal with varied demand situations. The digital analytics will help you accomplish financial goals with forecasted success by managing your inventory and sales orders efficiently.

5) Information quality enhanced by eliminating human errors.

It is well known that the importance of technology quality of information complement each other because manual filtering might lost. Although computerised information operations prevents manual mistakes, it also makes the process less visible in some means and therefore, wrong information or low value information might be generated if the information input is already of poor quality and not thoroughly checked, so people need to very careful while inputting the data. A difference can be generated between the volume of information and the richness of information exchange.The sharing of information in operational language involves more agility, commitment and maintenance to enhance the quality of any enterprise which is advantageous in the light of supply chain network.

Jayesh Logistics is a Durgapur, Kolkata based strategic, technology-based logistic company. We at Jayesh Logistics, are committed to help you reach your goals, personalize your logistics experience and provide complete support to ensure smooth operations. We’ll help you zero in on your highest opportunities for larger revenue or affordable costs, and then come up with cost effective solutions to help you use these options to your benefit. Contact us today for the digital friendly, technology based opportunities for your business.